VT Polimer glue - CONCRETE CONNECT

zł55.99 zł60.99

Professional assembly adhesive for architectural concrete.

(zł401.37 / m2)

Unique designs of 3D tiles available in our store will modernize any interior space.

Professional customer service

Secure delivery sent directly to you

The 3D decorative panel made of architectural concrete PB11 "Cub" is an element in the shape of rectangles of various depths, creating a three-dimensional surface with a very interesting, unique appearance. The concrete decorative wall panel is a perfect solution for modern interiors.

Concrete slabs can be used both indoors and outdoors as a form of the facade. In combination with various patterns of 2D panels available in our store (see products), you can create unique and modern interiors and building facades. The boards can also be successfully laid on fences and fireplaces due to their fire resistance.

The architectural concrete from which the offered VT series panels are made is chemically reinforced concrete with the use of coarser aggregate. Thanks to this structure, the produced slabs can be 1 cm thick, maintaining strength and durability. Reaction to fire - class A1.

Depending on the room in which we want to use the slabs, they should be properly impregnated. For this purpose, we recommend using an impregnation from our offer (impregnation - buy the product).

In addition, we offer factory-impregnated slab options for even greater convenience and speed of installation. Just select this option from the drop-down list of available product combinations.

Our slabs can be easily cut to the desired size using diamond discs for concrete. You can use a regular angle grinder or a circular saw for this purpose. Cutting should be done dry without the use of water.

For the convenience of our customers - on request - we can cut the ordered slabs to the selected size. The cost of such a service is PLN 50 gross per running meter of cut.

Using drills and hole saws for concrete, mounting holes for sockets or TV brackets can be made in the slabs. All holes must be drilled without hammering.

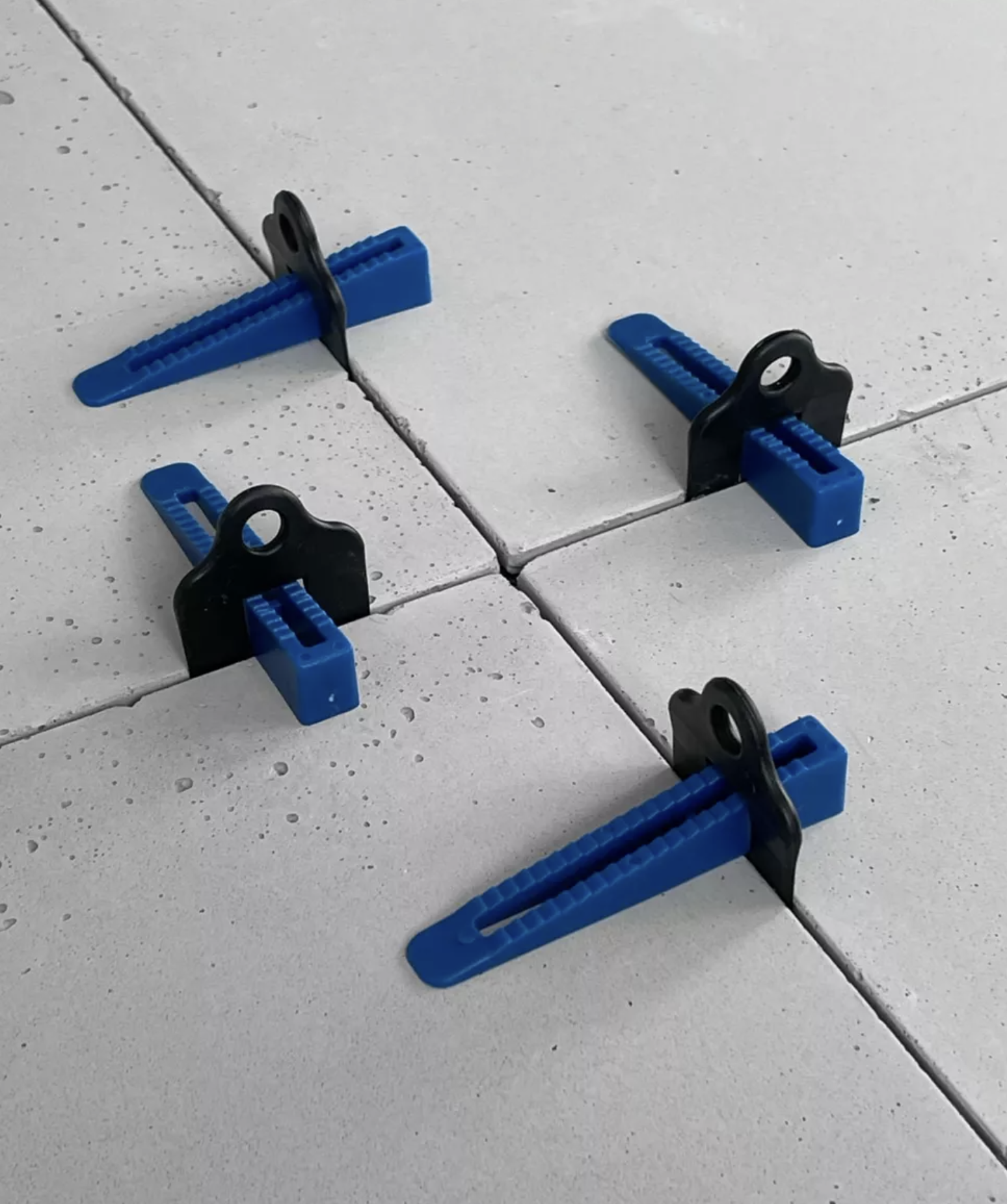

All you need is polymer glue or two-component C2TE glue - available in our store (does not require anchors, additional reinforcements or other stabilizers in the case of internal walls). The slabs can be mounted to OSB, MDF or GK slabs if you do not want to sand the paint and putty on the substrate. The gypsum substrate is not suitable for direct bonding of architectural concrete.

The complete, detailed installation and storage instructions after delivery are available for download here.

5-year warranty against damage after installing the slabs, using a dedicated mounting kit, listed in the "necessary mounting accessories" section.

Cracks, deformations, and falling off the wall - may occur if the recommended accessories are not used.

Read the assembly instructions before starting any assembly work.

Calculator

CalculatorStep 1 - enter the dimensions of the wall

The calculator will calculate, based on them, the number of panels and accessories needed for installation. Then, from the available slab sizes, select the slab size and the horizontal or vertical orientation.

Step 2 - see the proposed arrangement of slabs on the wall

The calculator takes into account cutting up to two elements with a factory-cast edge from one slab. You will be offered the number of slabs along with the necessary accessories for assembly.

Step 3 - add products to the cart

After going to the cart, you will receive additional information on delivery costs.

Thanks to the one-step shopping cart, the ordering process is very simple and fast. In one window, you will enter shipping data, and invoices, choose the transport and payment method, and finish the whole process with fast payments by Przelewy24.pl or a traditional transfer.

▫️ For the installation of concrete panels, it is recommended to use dedicated mounting accessories also available in our store.

▫️ Possible factory deviations of architectural concrete slabs should be reported before installation.

▫️ Due to the characteristics of architectural concrete, differences in the number and size of pits on the surface of individual slabs are possible. Color and dimensional discrepancies (+/- 3 mm) are also allowed.

▫️ Before installation, check the entire batch of slabs and plan the distribution of individual slabs and the order of their assembly by choosing slabs from different places on the palette to preserve the natural appearance of the wall.

▫️ For demonstration purposes, the slabs in the photos, from the implementation and visualizations are shown in different color versions. To make a color selection based on actual colors, we suggest purchasing a concrete slab sample book.

▫️ The colors displayed on customer monitor screens may differ from the actual color due to discrepancies in the matrices and calibration of the displays.

▫️ The slabs may have cast residues on the edges, which the assembly team should sand down before laying the slabs on the wall.

Data sheet